Welcome to Cortex Robotics! They’re here to introduce their offer for detecting wire bond defects. At Cortex Robotics, they are committed to ensuring the reliability of your electronic components. Their expert team is ready to help you identify and address any wire bond issues, so your devices can function flawlessly. Let’s explore more.

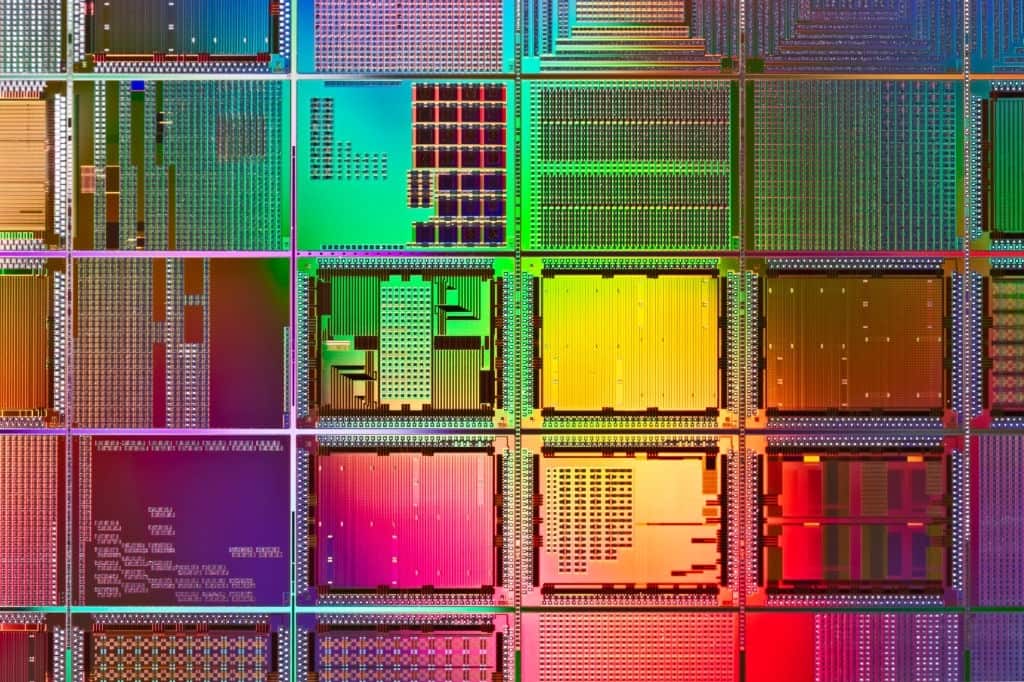

Wire bonding is very important in making electronics. It helps connect tiny electronic parts using thin wires made of materials like aluminum or gold. This connection makes sure the electronics work well. In this essay, we will talk more about why wire bonding is important in the electronics industry.

First and foremost, wire bonding serves to establish electrical connections between different components within an integrated circuit or between the IC and its packaging. These connections are essential for the transmission of electrical signals and power supply, enabling the IC to function as intended. Without wire bonding, the numerous tiny components within a semiconductor device would remain isolated, rendering the device useless. So, the main job of wire bonding is to connect these parts together and make sure they work well together.

Wire bonding is crucial because it ensures that electronic connections are strong and function properly. Electronic things can go through different conditions like hot and cold temperatures, wetness, and things pushing on them. Wire bonding helps make sure the connections stay strong even when these things happen. They use special wires made of gold or aluminum that are really good at carrying electricity and don’t get damaged easily. This helps keep the connections strong and stops problems with signals or electricity not working.

Wire bonding is very important in making small electronic devices. As technology gets better, people want electronic things to be smaller and tinier. Wire bonding allows for the creation of intricate and compact connections within the limited space available on semiconductor chips and packages. This miniaturization is essential for the development of smaller, more portable, and more powerful electronic devices, from smartphones to medical implants.

Moreover, wire bonding contributes to cost-effectiveness in electronics manufacturing. It is a well-established and relatively cost-efficient process compared to alternatives like flip-chip bonding. Its simplicity and ability to work for many different things make it a top pick for many uses, like in things people use every day, like phones and cars. This helps companies save money and helps people pay less for electronic stuff in stores.

Additionally, wire bonding is crucial for facilitating thermal management in electronic devices. ICs generate heat during operation, and efficient heat dissipation is essential to prevent overheating and ensure optimal performance and longevity. Wirebonds can serve as pathways for heat transfer, helping to dissipate heat away from the ICs and into the surrounding packaging or heat sinks. This thermal management capability is especially vital in high-power applications, such as microprocessors and power amplifiers.

To sum it up, wire bonding is an important part of making electronics. It helps make sure things connect well inside electronic parts, so they work right. It also helps make electronic things smaller, cheaper, and cooler. This helps make technology better and makes smaller, cheaper, and better electronic stuff. As technology keeps getting better, wire bonding remains important for making electronics today.

Discover how Cortex Robotics can help you fix wire bond defects today! Take action now and explore their solutions to ensure flawless connections. Don’t miss out—visit their website or contact them for more information.